Search

2015 International Building Code, Chapter 1 Scope and Administration, Section 104 Duties and Powers of Building Official

[A] 104.11 Alternative materials, design and methods of construction and equipment.

2015 International Building Code, Chapter 1 Scope and Administration, Section 104 Duties and Powers of Building Official

[A] 104.11 Alternative materials, design and methods of construction and equipment.

Chapter 17 Special Inspections and Tests, SECTION 1703 APPROVALS

SECTION 1703 APPROVALS

1703.1 Approved agency. An approved agency shall provide all information as necessary for the building official to determine that the agency meets the applicable requirements specified in Sections 1703.1.1 through 1703.1.3.

Chapter 17 Special Inspections and Tests, SECTION 1703 APPROVALS

1703.4.2 Research reports.

Supporting data, where necessary to assist in the approval of products, materials or assemblies not specifically provided for in this code, shall consist of valid research reports from approved sources.

Addressing Product Innovation, Code Approval and Professional Engineering

The “alternative materials, designs or methods of construction,” found in the building code are often misunderstood, leading to the statement: “I need an ICC report.”

Code compliant use of Metal Plate Connected Wood Trusses (MPCWT) to support brick veneer can be accomplished by both individual designs and by adhering to the recommendations that follow within this report. This discussion focuses on a common use of MPCWT’s; the gable end at the transition from a wider section of a building to a narrower section.

This presentation provides information on truss submittal packages.

To download the full presentation, choose a link below.

There are circumstances when the deflection requirements for a specific structure that utilizes floor trusses as structural members are questioned. The current residential and commercial building codes provide minimum design requirements for loads and for deflection of structural floor members, which also apply to floor trusses. The building designer may specify more stringent requirements. This research report will focus on manufacturer or trade association deflection requirements for a number of floor topping/covering related products

The capacity of a ribbon board and its system through the composite of the ribbon board, floor sheathing and bottom plate of the wall has not been ascertained. In order to provide better guidance, a series of tests were conducted in order to determine the capacity of the ribbon board system.

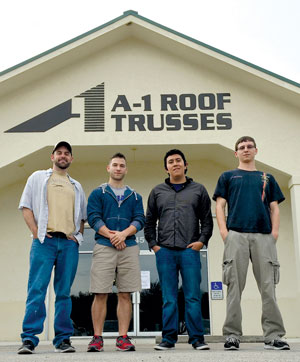

Component manufacturers who dedicate time and effort into developing a systematic, ongoing process for outreach and recruitment insist it’s more than worth the investment! While there isn’t one right way to find, assess, and grow new talent, read about approaches to workforce development.

Investing in continuing education can be a powerful way to communicate to your existing employees their value to your organization, as well as improve their existing skills.

Learn about component manufacturers taking a proactive approach to their workforce development needs in past SBC Magazine articles and SBCA webinars.

This presentation provides information on recent fire testing of floor systems in an effort to discuss 2012 IRC Section R501.3 and 2015 IRC Section R302.13 and the use of gypsum wallboard in single membrane floor protection.

To download the full presentation, choose a link below.

This presentation shows how code compliant use of MPCWT to support brick veneer can be accomplished and can be applied to many different situations utilizing MPCWT’s.

To download the full presentation, choose a link below.

2012 International Residential Code

Chapter 5 Floors (search for R501.3)

This presentation provides information on and requirements for the use of metal channel to meet lateral restraint/bracing requirements for metal plate connected wood trusses.

To download the full presentation, choose a link below.

The truss industry is currently employing ASCE as its source for the loading of live loads to the bottom chord of trusses for uninhabitable attics, in accordance with the International Residential Code and the International Building Code. However, there currently is a discrepancy between ASCE 7, the IBC and the IRC. This report examines the discrepancy and the correct loading for proper truss design.

QUALITY Speaks for Itself

QUALITY Speaks for Itself

Listed below are Frequently Asked Questions (FAQs) about SBCA In-Plant Wood Truss QC and SBCA’s Certification program. If you have any questions that were not addressed above, please contact SBCA staff.

Controlling sound transmission in buildings through wall, floor and ceiling assemblies is important for the comfort level and enjoyment of building occupants as they live, work and play in these buildings. This report aims to explore the methods one can use to reduce sound transmission in assemblies constructed with wood trusses.

Many factors go into classifying buildings. Each type will have different allowable height, allowable number of stories and allowable area limitations based on the classification. This educational program will focus on Type III-A building construction using fire retardant treated wood (FRTW).

To download the full presentation, choose a link below.

This program provides information on metal plate connected wood truss floor systems and managing vibrations.

To download the full program, choose a link below.

Addressing Product Innovation, Code Approval and Professional Engineering

The “alternative materials, designs or methods of construction,” found in the building code are often misunderstood, leading to the statement: “I need an ICC report.”

ASCE/SEI 7-16 Minimum Design Loads for Buildings and Other Structures has revised Chapter 30 regarding Components & Cladding (C&C) wind loads on roofs. This report clarifies the type and scope of changes being made that will also change in the 2018 edition of the model building codes.

This project overview graphic provides a quick visual representation of the time, labor and waste benefits of using components as well as a more in-depth look into the specific savings in each area based on both the 1995 and 2015 Framing the American Dream studies. This full-page infographic is great to use as a leave-behind with customers or presentation attendees to illustrate the full benefits of framing with components.

In each Framing the American Dream study, two identical buildings were framed, providing an apples-to-apples comparison of stick and component framing methods. This infographic focuses on what we learned in each area by the numbers.

The 2015 Framing the American Dream study was unique in its use of floor panel systems. This infographic looks specifically at the labor savings of installing floor panels versus the floor installation in the stick-built home.

The results of the Framing the American Dream study looked closely at the total number of hours, broken into discreet framing tasks, to determine how long it took a framing crew to complete each home. This infographic makes the person-hour savings of using components clear at a glance.

The Framing the American Dream study shows that a stick-framed house creates nearly 30 times more jobsite waste than a component-framed house.