Search

Controlling sound transmission in buildings is an important serviceability issue. This presentation explores methods of reducing sound transmission in assemblies constructed with wood trusses.

To download the full presentation, choose a link below.

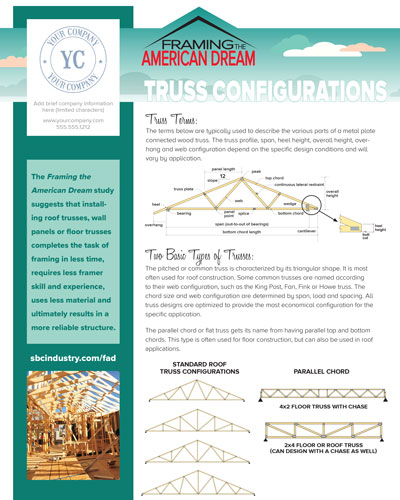

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, requires less framer skill and experience and ultimately results in a roof that enables more open and flexible floor plans. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality roof trusses to their customers.

Framing the American Dream data suggests that installing floor trusses requires less framer skill and experience, results in a floor that requires less bearing locations and more effectively accommodates HVAC, plumbing and electrical infrastructure. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality floor trusses to their customers.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in less time, requires less framer skill and experience and ultimately results in a more reliable building envelope. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality wall panels to their customers.

According to industry surveys, lumber constitutes roughly 40 percent of the cost of manufacturing a structural component. As a consequence, an adequate supply of North American softwood lumber is vital to the success of component manufacturers. Insect infestations and wildfires (natural forces), as well as protectionist trade actions and logging restrictions (man-made forces) can have a significant impact on the available supply of lumber. Forces that constrain supply at a time when demand increases (i.e. growth in residential construction), can have a severely negative impact on the stability of lumber costs.

This Research Report will look specifically at the sill plate requirements according to the 2009, 2012, and 2015 International Residential Code (IRC) and International Building Code (IBC) and clarify if a sill plate is required in the following conditions:

- Flat truss bottom chord bearing on ICF wall.

- Flat truss top chord bearing on ICF wall.

- Roof truss bearing on ICF wall.

SBCA’s library of technical design and installation best practices has been expanded over the past year to help CMs navigate a wide array of code-related challenges in their markets.

If you’ve been in the truss industry for any length of time, there’s one phone call you absolutely dread receiving: “We have a problem; your trusses collapsed!”

For this general manager, other start-ups were more of a model than other CMs.

Quality marks are not substitutes for grade marks—FRTW will include both!

Your company does it every day: load components and deliver them to jobsites. Ben Vadnais, assistant plant manager at Windsor Building Systems, has a few tips for keeping your loading and delivery operations running as smoothly and safely as possible.

In May 2007, SBC Magazine highlighted the uniquely curved trusses used for the “keeping room” of a custom home in Cherry Hills Village, Colorado.

The concrete podium of the mixed-used Mercer building sat out the recession. Now, the redesigned building is one of a handful of developments creating a new high-rent suburb of Las Vegas.

On February 7, 2017, the structural building components industry lost one of its leading advocates and innovators, Dwight Hikel. His contributions to the industry can be found today not only in the success of his company, Shelter Systems Limited, but also in the words and actions of many of the industry’s leaders who were his peers and fellow members of the Structural Building Components Association (SBCA).

In an industry that requires competition and innovation, one man separated himself from all the others for over forty years: Dwight Hikel. Many in the industry know his story but some may not. Shelter Systems Limited started out as a small, 14,000-square-foot plant in 1976 and has grown into a cutting edge, 120,000-square-foot truss manufacturing facility. That kind of growth doesn’t happen by accident.