Search

A spring Wisconsin snowstorm demonstrates how a building design practice may lead to higher risk.

building design review and approval process, and the

issues it can create for component manufacturers.

Getting information up front on sprinkler systems can ease the design process.

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, requires less framer skill and experience and ultimately results in a roof that enables more open and flexible floor plans. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality roof trusses to their customers.

Depending on the type of fire-retardant treatment (FRT) used, materials may require a change in design values and reduction in connector capacity. This report intends on providing a clear perspective of interiror FRT wood used in Truss designs.

- SCORE is a new marketing program for WTCA component manufacturer members.

- To earn a SCORE certification, manufacturers must participate in programs like Operation Safety, In-Plant WTCA QC and Truss Technician Training.

- When automated component saws became widely used in the ‘90s, truss tables became the new shop bottleneck.

- Laser projection systems and automated jigging systems offer two solutions to this bottleneck.

- It is not correct to assume that a truss designed with the least amount of board footage will always result in the most economic option.

- There is a point where the board footage cost of the high grade smaller member equals the cost of a larger, lower grade board.

- One component manufacturer found out that supplying green-built trusses can be very costly.

- Eco-certifiers like FSC and SFI impose strict chain of custody requirements on secondary lumber product manufacturers like CMs.

- In the last year SBCRI testing has helped us measure web forces, equalize load distribution and develop computerized truss models.

- Get critical market data from SBC’s new Market Analysis Service.

- Gypsum board is the most critical element in the fire endurance performance of cold-formed steel and wood truss assemblies.

- When adding insulation to a tested assembly, plan for an equivalent or greater plenum space.

- Bob Becht, "Mr. Truss Photo," takes digital technology to plant safety.

- Showing safety and health issues in a PowerPoint® presentation helps the staff create innovative policies to improve workplace safety.

High-stakes competition – at the table, out in the wind, and on the court – showed BCMC attendees know how to enjoy themselves both on and off the show floor. Congratulations to all the BCMC winners!

Whether it’s a major or minor part of your business, selling trusses to lumberyards, distributors and other manufacturers can be a significant risk. Learn how to limit your liability and manage your risks in resale contracts.

SBCA makes these Structural Details available to architects, engineers, contractors, designers, code enforcement officials and others involved in construction applications using metal plate connected wood trusses (MPCWT). SBCA hopes that these details will be of value, save time in the design process, and educate those in the proper application of MPCWT.

SBCA’s latest testing promises value for all CM

Looking for an economical way to add square footage and an alternative to decreasing spans? Read on!

While the perception of floor vibrations is subjective from one person to the next, overall floor systems which exhibit lower deflections and less acceleration from vibration sources tend to be perceived better than other designs. To accomplish this, the designer may elect to do one or a combination of things, covered in this report.

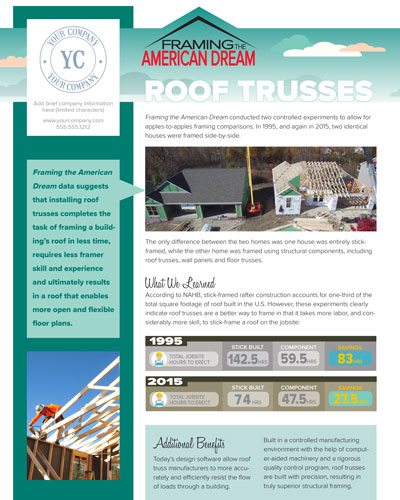

This time-lapse video provides a side-by-side comparison of two identical homes being framed. The only difference between them is the house on the left was stick-framed on site, while the house on the right was framed using floor trusses, wall panels and roof trusses. The video provides clear proof that structural components are the better way to frame.

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, requires less framer skill and experience, and ultimately results in a roof that enables more open and flexible floor plans.

Reach your builder customers with this colorful, customizable brochure that highlights the benefits of using roof trusses.

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, requires less framer skill and experience, and ultimately results in a roof that enables more open and flexible floor plans.

Reach your builder customers with this short, informative video that highlights the benefits of using roof trusses.

Many thanks to MiTek for generously funding the production of this video.

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, allowing the same framing crew to complete more roof projects over time.

Reach your framer customers with this short, informative video that highlights the benefits of using roof trusses.

Many thanks to MiTek for generously funding the production of this video.

- WTCA is putting together a “Guide to Loading and Transporting Wood Trusses.”

- The Federal Motor Carrier Safety Admin-istration recently established new guidelines for proper securement of cargo transported for commercial purposes.

- Under these new guidelines, you may want to reevaluate the quantity and meth-od you currently use to secure trusses to the transporting vehicle.

- This issue of SBC Magazine covers manufacturing issues and houses the BCMC 2005 Recap, complete with exhibitor photos, a summary of the educational sessions and other highlights.

- This issue’s cover story features Bama Truss & Components, a wood and steel component manufacturer in Shelby, AL that services the multi-family and commercial building industry.

- Other feature articles highlight combined U.S. and Canadian lumber species groups, proper crane hoisting and rigging guidelines, and a new Truss Technician Training recertification process.

- To comply with the provisions of the model code, a method or material must meet the requirements of the referenced standard

- A Project Committee has been formed to evaluate the 2002 edition of ANSI/TPI 1.

- WTCA is planning to propose changes to the I-Codes for the 2007 code cycle that will move in the direction of having the metal plate connected wood truss requirements currently included in the IBC and IRC also placed into TPI 1 so that both are consistent and ultimately most of the information about truss design and construction will be in TPI 1.

- This event is one example of WTCA’s work to provide solid technical education on the fire performance of trusses.

- The goal of the tour was to listen to the concerns of the fire service about structural building components in modern building construction.

- The fire service was very impressed with the level of sophistication programmed into the truss design software, asking questions about how it could be integrated into the pre-fire planning process.

- Imagine taking a horizontal slice of a hard-boiled egg and looking at it from the top. Now imagine designing roof trusses to fit on top of that shape and completing the job within budget.

- Pioneer came up with the idea of drawing the trusses first in CAD to represent the roof in true 3D.

- Paul Lenauer credited technology with making this project possible, while the project’s architect credits structural building components with helping make his vision a reality.

- Without the diagonal brace, the only thing the lateral member(s) ensures is that the webs to which they are attached will be-have as a unit and buckle together in the same direction if and/or when the buckling load is reached.

- The single diagonal brace and web reinforcement options satisfy the need for bracing individual trusses and truss members, but not the stability bracing of the entire building system.

- BCSI-B3 Web Member Permanent Bra-cing/Web Reinforcement provides indus-try recommendations and methods for restraining web members against buckling.

- Gene Woloveke started his career at Idaco Machine & Equipment Company in the late 1940s.

- Early on, the company owned a sawmill machinery manufacturing division as well as a lumber division.

- In the 1950s, Idaco ventured into the truss business, selling home packages and manufacturing truss equipment for component manufacturers.

- Gene designed and built the first automated component saw by hand.

- Idaco was among the first companies to partner with A. Carroll Sanford, inventor of the light gauge steel connector plate.