Fire Protection - Floor Systems

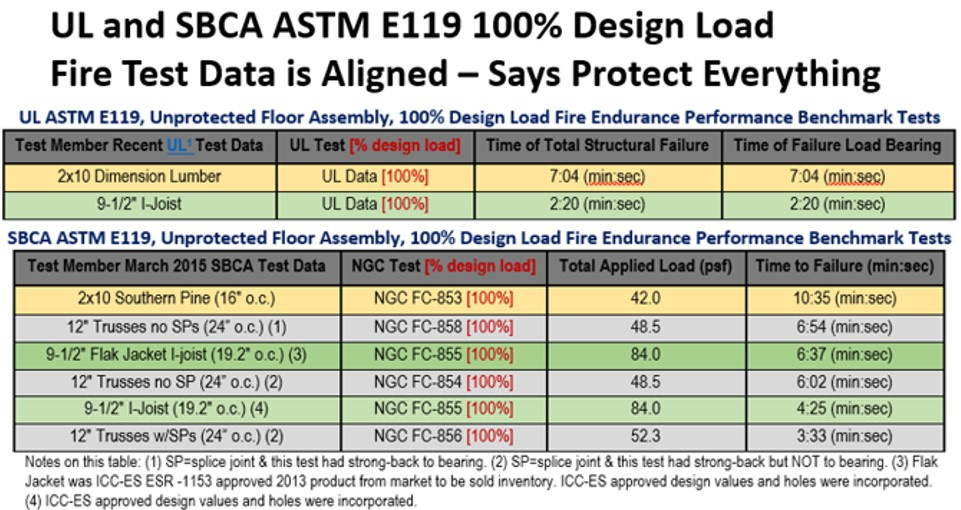

Recent ASTM E119 testing (using 100% design load conditions as required by that standard), conducted independently by Underwriters Laboratory (UL) and NGC Testing Services (NGC), confirm that an unprotected floor assembly constructed of 2x10s or Flak Jacket coated I-joists do not provide “equivalent performance” to a floor assembly that has a ½” gypsum wallboard. A ½” wallboard membrane ceiling, as prescribed by IRC-12 R501.3 and IRC-15 R302.13, has 26 minutes of performance as tested by UL.

Standardized E119 testing (see graphic at right) shows all unprotected structural floor assemblies perform for far less than the 15-minute membrane time provided by a ½” gypsum wallboard membrane ceiling, as defined by code IBC-12 Section 722.6.2.

UL concludes on page 67 of its test report, “There are little if any warning signs of collapse so it is very important to understand the hazards associated with a basement fire because the consequences of falling through a floor into a basement fire are pinnacle.” Further, on page 66, the UL test report concludes, “This [the fire service response time scenario] assumes ….. the fire department begins their firefighting operation in 8 minutes…. This emphasizes the importance of protecting all types of flooring systems, including dimensional lumber.” (emphasis added.)

A failure to act on public domain knowledge could easily lead to a firefighter falling through an unprotected 2x10 or Flak Jacket coated I-joist floor and being maimed or killed due to an erroneous assumption the system adheres to the traditional “20-minute rule.” In contrast, by providing a ½” gypsum wallboard membrane ceiling to all floor systems, 20 minutes of actual performance time is likely to be present.

Top Resources

This webpage provides links to several articles that analyze recent ASTM E119 unprotected floor assembly fire testing and the conclusions that can be drawn from the test results.

This webpage directs readers to published resources that answer some of the most pertinent questions regarding the fire performance of floor systems and the impact of installing a gypsum membrane.

This is the language found in the 2012, 2015 and 2018 model International Residential Code (IRC) that requires a gypsum membrane be applied to certain unprotected floor assemblies.

Best Practices

SBCA has worked diligently to undertake the research and testing needed to confirm the unprotected assembly fire endurance performance facts available and to develop code change proposals that align with those facts. Since this work began in 2009, SBCA has proposed that a single membrane be applied to all unprotected structural elements because of its life-safety benefits. To that end the core best practice code language follows:

R501.3 Fire protection of floors. Floor assemblies, not required elsewhere in this code to be fire-resistance rated, shall be provided with a 1/2-inch (12.7 mm) gypsum wallboard membrane, 5/8-inch (16 mm) wood structural panel membrane, or equivalent on the underside of the floor framing member as defined by performance equivalent to 26 minutes using ASTM E119 standard fire endurance testing with a superimposed load simulating a maximum load condition (i.e. 100% design load).

And deleting Exception 4 -- Wood floor assemblies using dimension lumber or structural composite lumber equal to or greater than 2-inch by 10-inch (50.8 mm by 254 mm) nominal dimension, or other approved floor assemblies demonstrating equivalent fire performance.

SBCA therefore recommends jurisdictions immediately amend the 2015 and 2018 IRC model code after its original proposed amendment RB69.