Search

- The required bearing length provided on the Truss Design Drawing is based on the lumber used in the truss.

- The bearing area for the wood wall or beam may need to be increased to prevent crushing of these members.

- Table 1 includes the maximum allowable reaction load that selected species of lumber used as wall plates can resist without excessive crushing.

- If knee braces are shown, the trusses must be designed for them using the loads provided by the RDP.

- In the Midwest knee braces are used in many post frame buildings for which an RDP is neither required nor involved.

- This rapidly forces the Truss Designer into the position of designing building elements that ought to be specified by the person responsible for the overall building design.

- Bevel cutting can be a very dangerous operation in the truss plant especially since 90 percent of One Minute Poll respondents say they use a table saw.

- There are about six different methods of installing valley trusses that are used in the field.

- Dead loads are projected horizontally for truss design.

- Truss technicians must be clear on whether they need to adjust the input design dead load values for slope or if the software will do it for them.

- Slope adjustments become more critical with steeper pitches.

- The following Technical Q&A has been updated from the version that appeared in the 2006 June/July issue of SBC.

- Lateral restraints are installed to reduce the buckling length of the web(s), but must be restrained laterally to prevent the webs to which they are attached from buckling together in the same direction.

- BCSI-B3, Permanent Restraint/Bracing of Chords and Web Members, provides general industry recommendations and methods for restraining web members against buckling.

Automatic sprinkler systems are an effective method of providing fire protection and are used in many applications in which metal plate connected wood trusses are used. This session will review the three types of automatic sprinkler systems specified in the building codes and what needs to be considered when designing trusses to be used with a sprinkler system.

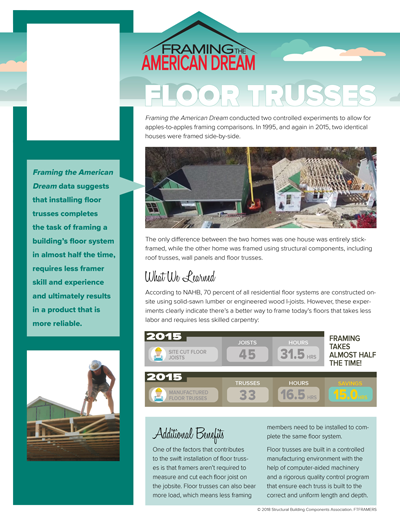

Framing the American Dream data suggests that installing floor trusses completes the task of framing a building’s floor system in almost half the time, requires less framer skill and experience and ultimately results in a product that is more reliable.

Reach your framer customers with this colorful, customizable brochure that highlights the benefits of using floor trusses.

This webinar is the fifth in a series that will discuss special design situations involving “leg down” trusses, horizontal deflection and scissors trusses, etc. Visit the webinar archives to view parts 1-4 of this series (see July 17, 2018, August 14, 2018, October 9, 2018 & February 5, 2019).

Take a closer look at weather’s effect on plate movement

The following article provides SBCA's proposed best practice Truss Placement Diagram note language for CMsto use as a standardize approach with respect to defining their scope of work.

Proposed Sample TPD Note Language

On every project, it's important to clarify the design responsibilities when metal plate connected wood trusses are incorporated into a building or structure.

- WTCA’s new Truss Technology Workshop (TTW) web site, ttw.woodtruss.com, offers a one-stop shop for continuing education (CEU) credits.

- The site is designed to serve as a year-round resource for those in professions who work with roof trusses, floor trusses, wall panels and related components.

- Users who purchase a year-long subscription also receive unlimited access to the site’s online resource library.

- The site offers component manufacturer members all the materials necessary to present their own live TTWs for free.

- Bama Truss & Components manufactures both wood and steel trusses for the commercial and multi-family building construction industry.

- When they first introduced their steel line in 2002, they made drastic changes in their design and manufacturing departments to separate the functions of the wood and steel divisions.

- The company has experienced more benefits than drawbacks as a result of ex-panding their operations to include steel trusses.

- This issue of SBC Magazine is devoted to design and engineering advancements.

- The cover story highlights a design challenge that Pioneer Truss couldn’t pass up. Though the structure was small, the effort it took to design and build the trusses with ultimate precision for it was not.

- In February, BMC West graciously welcomed members of the fire service to its facility in the Portland area. Atten-dees seemed most impressed with the truss design software and the overall level of professionalism displayed during the tour.

- John Meeks began his post-military car-eer in the commercial concrete industry.

- Meeks met Gang-Nail’s Cal Jureit in Florida, and joined Automated Building Components, Inc. as the Engineering Manager in charge of building franchise chains.

- He became involved in truss design engineering at ABC, and also took an interest in bracing and installation while inspecting a truss collapse.

- Throughout his career and still today, Meeks has made his mark on the wood truss industry as a respected forensic engineer.

- Contractors should install and brace trusses according to the Building Component Safety Information (BCSI) booklet.

- History has proven that truss instability and the variety of potential consequences due to this is typically the direct result of improper handling, installing, restraining and bracing of trusses.

- Most collapses will require a separate assessment by a professional engineer to determine the correct course of action.

- The topic of whether truss placement diagrams (TPDs) should be sealed continues to be misunderstood.

- The TPD should not to be viewed as an engineering document; it is provided to help the installer locate the trusses within the structure.

- A TPD is generally not prepared within the typical duties of an engineer and is therefore not typically prepared under the engineer’s direct supervision.

- Truss Designers are counseled to only undertake Building Designer responsibilities under a special set of circumstances.

- The Extreme build helped Northeast Panel & Truss dispel misconceptions about wall panels and led their builder customer to embrace the product.

- The experience convinced Amedore Homes that wall panels are quality products that are also efficient and economical.

- The project couldn’t have been completed in the given timeframe without the use of wall panels, roof truss and floor trusses.

- Cold-formed steel is gaining respect and popularity in the industry thanks to challenging design projects and diverse construction applications.

- M-Truss worked on a luxury condominium project in Las Vegas that called for steel radius trusses and radius wall panels.

- Companies like M-Truss have been successful by demonstrating the bottom line savings of cold-formed steel in the ease of installation and reduced labor costs.

- Andrews Truss designed and built the trusses for a cone-shaped tower measuring 75' tall and 21' across.

- The tower was part of a 4,000 sq. ft. vacation home in northwestern North Carolina located near the “Tail of the Dragon” highway.

- This was technician Phil Close’s first experience designing trusses for a tower this shape.

- The key, he said, was a lot of careful thought before beginning the design.

- Multiple-ply truss girders can be assembled in manufacturing facilities or at the jobsite.

- Specific ply-to-ply connections of multi-ply trusses are specified on truss design drawings.

- TPI 1-2007 defines multi-ply girder assembly requirements in section 7.5.5.1.

- Proprietary screw manufacturers will have recommendations on how to fasten plies together.

- Partition separation is often blamed on a condition known as truss arching.

- Wood may expand or shrink depending on its moisture content.

- The example given in Figure 2 shows that a 28-ft truss with 19% moisture content that dries to 7% may cause an upward deflection of about 0.7 inches.

- Many factors lead to partition separation; the only way to prove truss arching is to use a laser level to assess all the areas of potential movement in the structure.

- The IBC does not prohibit the use of exposed truss bottom chords.

- Since interior grade OSB is allowed on the underside of an exposed truss, it follows that there would not be a more stringent requirement for exposed trusses.

- The USDA Forest Products Laboratory’s Wood Handbook provides the average equilibrium moisture content of wood exposed to the outdoor atmosphere for various cities in the United States.

- East met West when Chinese Jiangsu Jifco Holdings went equipment shopping for a new truss and wall panel manufacturing facility in the U.S.

- Even though there were no skilled sawyers, operators, assemblers, or truss technicians available in China, Jay Halteman (Wood Truss Systems) was amazed at the Chinese’s capability and devotion to the project.

- For the new plant in China, Halteman chose what he believed to be the most reliable automated equipment that was also the easiest to operate and had extreme durability.

Framing the American Dream data suggests that installing floor trusses requires less framer skill and experience, results in a floor that requires less bearing locations and more effectively accommodates HVAC, plumbing and electrical infrastructure. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality floor trusses to their customers.

This webinar will discuss industry recommendations per BCSI’s Jobsite Package documents for storage, handling, installing, restraining and bracing of metal plate connected wood trusses. The session will provide an overview of B1, B2, B3, B4 and B11, which comprise a standard jobsite package as recommended by SBCA. This material includes important information for the various parties involved in the construction process including, the contractor, building designer, truss designer, truss manufacturer and code official.

The following article provides SBCA's proposed best practice Truss Design Drawing (TDD) Cover Sheet language for CMs to use as a standardize approach with respect to defining their scope of work. The grey highlighted text ties most directly to the commentary provided after the proposed sample language.

Proposed Sample TDD Cover Sheet Language

The following provides SBCA's proposed best practice contract language for CMs to use as a standardize approach with respect to defining their scope of work. The grey highlighted text ties most directly to the commentary provided after the proposed sample language.

Proposed Sample Contract Language

In order to promote the safe installation of building components including trusses, manufacturers send out a Jobsite Package to the construction site with the truss delivery. These Jobsite Packages include the Truss Submittal Package. The Truss Submittal Package includes the information that if required will be submitted to the Contractor/Building Designer, who if required will submit it to the local building official.

The following article provides SBCA's proposed best practice Truss Design Drawing (TDD) warning note language for CMs to use as a standardize approach with respect to defining their scope of work.

Proposed Sample TDD Warning Note Language