Search

The repair and modification of metal plate connected wood trusses can be a very complicated subject, because each situation must be analyzed individually. Common situations that require repairs include: damage to the truss from delivery, handling, installation, adverse environments, fire, and manufacturing mistakes. Whatever the reason for a repair, the principles followed are similar. The truss repair must result in a truss that is able to carry all loads intended for the truss. This webinar covers the key concepts involved with a truss repair.

The following resources are for specifying metal plate connected wood trusses:

- Four areas of concern will help identify the hazards and reduce the risks associated with handling finished trusses: forklift limitations, truss limitations, storage and loading.

- Use a proper spreader bar to transport long span trusses.

- Trusses are not designed to carry significant amounts of lateral load which means that pressure placed on the "face" of a truss can cause damage.

- Many employers won’t hire ex-felons.

- The industry has a chronic shortage of skilled truss technicians, so setting up a prison design department was the perfect solution for Stark Truss.

- The truss industry has several success stories of helping former felons reintegrate into life.

- A custom home in a suburb of Denver was originally designed with a stick-framed Keeping Room.

- The builder and framer were skeptical about trussing the roof until the designer provided a full-size sample truss.

- The prototype convinced them that the Keeping Room should be trussed.

- BCSI recommends using the Alternate Installation Method for lifting and setting truss assemblies.

- The top chord, bottom chord and webs should be braced prior to lifting the trusses.

- Always consult a Professional Engineer when setting an assembly with long-span trusses.

- A common mistake is thinking that the truss design drawing provides all of the bracing requirements for the truss.

- In the 2006 Edition of BCSI continuous lateral brace has been replaced in by the term “continuous lateral restraint.”

- Bracing the lateral restraint is critical for ensuring truss stability; failure to do so can result in serviceability problems or structural collapse.

- There are many guidelines and recommendations in place to ensure trusses are installed and braced properly.

- Truss Design Drawings show the truss calculation and engineer stamp, but usually show limited bracing.

- It is our hope that BCSI recommendations are followed in the field, but we cannot enforce them.

- Many employers won’t hire ex-felons.

- The industry has a chronic shortage of skilled truss technicians, so setting up a prison design department was the perfect solution for Stark Truss.

- The truss industry has several success stories of helping former felons reintegrate into life.

- Are you seeing the same objections to wall panels that you had with selling trusses?

- Labor demographics today will drive wall panel sales much like labor savings drove truss sales in the 1950s.

The following provides SBCA's proposed best practice truss submittal package language for CMs to use as a standardize approach with respect to defining their scope of work. The grey highlighted text ties most directly to the commentary provided after the proposed sample language.

Proposed Sample TDD and TPD Submittal Transmittal Language

Communication is key to a successful construction project.

ASCE/SEI 7-10, Minimum Design Loads of Buildings and Other Structures, lists two methods for calculating wind pressures: Main Wind Force Resisting System (MWFRS) and Components & Cladding (C&C). This report will provide information to assist the building designer in deciding upon the appropriate analysis method for uplift due to wind loading.

- The IBC and IRC 10 psf attic live load is a non-concurrent live load applied as one of the load conditions that are checked when designing trusses.

- The IBC and IRC 20 psf attic storage load shall be applied only in areas intended for storage as clearly identified on the truss design drawings.

- A note will be placed on the truss design drawings identifying the storage load that was applied to the trusses.

- A new Truss Technology in Building document developed by WTCA due to members’ requests demonstrates proper truss hoisting techniques on the jobsite.

- Although the document gives recommendations for the handling of trusses, it is important to note that the general operation of any mobile crane must comply with OSHA standards.

- The TTB’s section on Load Positions, Movement & Rigging presents techniques that are likely to reduce crane damage to trusses.

- A new Truss Technology in Building document developed by WTCA due to members’ requests demonstrates proper truss hoisting techniques on the jobsite.

- Although the document gives recommendations for the handling of trusses, it is important to note that the general operation of any mobile crane must comply with OSHA standards.

- The TTB’s section on Load Positions, Movement & Rigging presents techniques that are likely to reduce crane damage to trusses.

- A massive custom home in the Florida panhandle called for long-span radius trusses that were designed and built by Builders FirstSource.

- The job was especially challenging because the 68-foot trusses were curved on both the bottom and top chords.

- The BFS team took special precautions when building the trusses to prevent workers’ injuries and damage to the trusses.

- Solar panels—devices that convert solar energy into electricity or heat—are often installed in trussed and conventionally framed roofs.

- To determine if a truss can withstand the load of a solar panel, add the value of the panel to the maximum top chord dead load capacity.

- If a panel can be applied to a conventionally framed roof with the same design load capacity as a truss system, the application should also work in the trussed roof.

- The relatively short spans and light end reactions associated with most jack trusses makes toe-nailing an efficient and effective attachment method.

- An open end jack truss (see Figure 1) meeting the same design parameters would perform in a similar manner as a rafter and ceiling joist and generate comparable reactions. The top chord and bottom chord of the jack truss should correspond to the rafter and ceiling joist tables provided in the code. For these situations, the nail connections specified by the code are also applicable to jack trusses.

This webinar is a second in a series that will discuss the minimum load requirements for the design of trusses that are subject to building code requirements.

This webinar is a third in a series that will discuss the minimum load requirements for the design of trusses that are subject to building code requirements.

The SBCA Truss Plate Council, Executive Committee and Board of Directors have been working on individual sample best practice language for component manufacturers. They are as follows:

BCSI Canada includes Canadian references, installation tolerances aligned with local practices, and design related tables consistent with the Canadian design standard.

This webinar provides an overview of important information contained in the BCSI booklet. Attend this SBCA Webinar and have a change to win a copy of the Building Component Safety Information Book.

The truss industry uses about 36 percent of the framing lumber consumed in the U.S. Dimensional framing lumber is graded for structural applications like joists, rafters and trusses. These structural framing grades can be determined by two methods—visual inspection or machine testing.

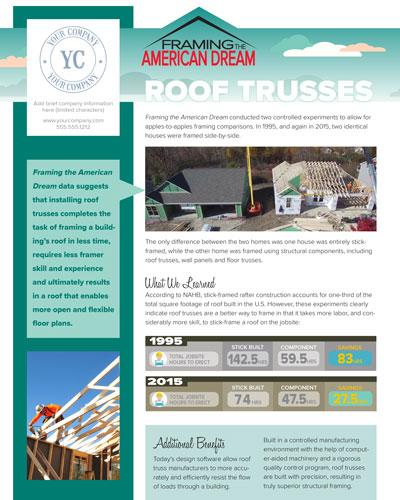

Framing the American Dream data suggests that installing roof trusses completes the task of framing a building’s roof in less time, allowing the same framing crew to complete more roof projects over time.

Reach your framer customers with this colorful, customizable brochure that highlights the benefits of using roof trusses.

- Truss plant tours give those outside our industry a chance to experience our component manufacturing industry and change their perceptions.

- A truss plant tour is easy to give a group presentation about. Just use your passion, your profession and your expertise!

- Truss plant tours have worked in the industry’s educational favor.

- The WTCA-NY made a significant educational impression in the New York State Building Officials Conference’s (NYSBOC) perception in October 2006.

- The tour shed a lot of light on the truss industry for building code officials and fire service members.

- Most truss shops use one of four factors that work "on average" to estimate labor.

- Labor estimates based on averages do not take into account complex jobs.

- In the truss industry, the Houlihan Method is one example of lean manufacturing.

- Employing proper time standards provides a solution to estimating labor.

- Deflection limits for trusses with habitable spaces differ depending upon the building code.

- The 2009 IRC references TPI 1-2007; it defines a live load deflection limit of l/360 for these trusses.

- TPI 1-2002, which the 2006 IRC references, does not contain a live load deflection limit.