Search

- WTCA-IL hosted a truss plant tour for the fire service personnel of MABAS division 10 at Neumann Distribution Centers in northern Illinois.

- Planning the flow, timeline, and coordination of a truss plant tour prior to group arrival is critical to its success.

- The tour also included a Carbeck presentation where many concerns and questions were addressed.

- WTCA-IL and MABAS 10 have laid the groundwork for a mutually beneficial relationship.

- Bryan Hill stood before the California Building Standards Commission to defeat an amendment requiring truss placement diagrams to be sealed.

- WTCA staff realized that the Department of State Architects did not understand the professional liability that truss design engineers face when they seal layouts.

- In the end, Hill was successful in getting the requirement removed from the 2006 California Building Code.

- This issue of SBC contains the BCMC 2007 Show Guide starting on page 50.

- Learn about how to increase cold-formed steel truss market share with some tips from Cascade Mfg Co on page 24.

- Read "Record Retention—Reason & Risk" on page 28 for an update on how long you should keep important documents.

- New methods for determining bracing requirements for wood trusses are examined on page 94.

- Staff travel to chapters may be reduced. Instead, the use of Internet technology could be cost-effective alternative to live meetings.

- Staff will monitor recent changes in immigration policy and provide updates through SBC Industry News and Legislative Alerts.

- Component manufacturers were encouraged to keep up on the fire performance of wood trusses, information from Carbeck, and team up with staff on truss plant tours.

- Historic All Saint’s Church in Stuart, IA burned in 1995, and was rebuilt with building components in 2008.

- The project team included SBCA member Lumber Specialties, who designed and built an intricate roof truss system for the main dome of the church.

- To properly transfer loads, the trusses tied into custom steel compression and tension rings placed in the center of the dome.

- WTCA Legal Counsel Kent Pagel has presented many of the risk management and liability avoidance programs, which will soon be available online in an up-dated and modified format.

- At BCMC 2004, one question in the Manufacturers’ Roundtable was the im-portance of handling truss collapses proactively and the need to establish guidelines on how to properly conduct truss collapse investigations.

- Truss or rafter uplift connections should be designed for wind load using ASCE 7 MWFRS method, while the member design of the individual truss should use C&C loads to generate member forces.

- Visit http://www.sbcindustry.com/kb/technotes.php for SBCA’s Tech Note on this issue.

- The SBCA Load Guide also contains information about uplift connections for structural building components.

- Conditions like deflection and vibration can occur in metal plate connected wood trusses even if they meet the building code and adequately transfer loads.

- When stone flooring is installed over wood frame construction, deflections not exceeding L/720 are recommended.

- The Building Designer is responsible for providing the deflection criteria and on-center spacing requirements to limit deflections.

- If no building design information is given, truss technicians should not assume deflection criteria of L/360.

- Brand your company as "The Solution" for all of your customers’ needs.

- If you offer wall panels, engineered wood products, steel trusses, and turnkey labor, or engineering design services in addition to wood trusses, be sure to market them.

- Work with the design and specifier community to help streamline the front end of the construction process and value-engineer structures.

Villaume Industries was incorporated 134 years ago, and it has stayed in business by sticking to the leading edge of innovation.

- Standard metal connector plates are suitable for use in lumber with moisture content of 19 percent or less and in building applications with no exposure to corrosive substances.

- Connector plates used in trusses exposed to high humidity or caustic chemicals may need to be treated to prevent corrosion.

- A variety of protective coatings can be applied to truss places in situations where special protection is necessary.

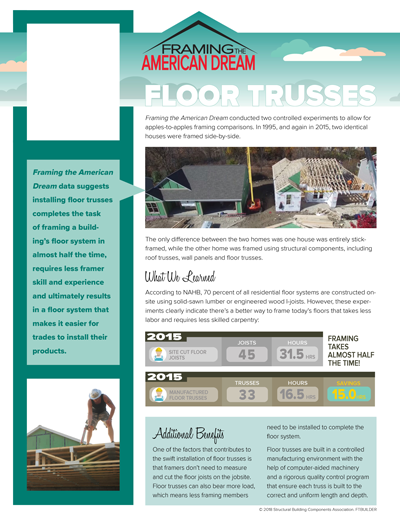

Framing the American Dream data suggests installing floor trusses completes the task of framing a building’s floor system in almost half the time, requires less framer skill and experience and ultimately results in a floor system that makes it easier for trades to install their products.

Reach your builder customers with this colorful, customizable brochure that highlights the benefits of using floor trusses.

Framing the American Dream data suggests installing floor trusses completes the task of framing a building’s floor system in almost half the time, requires less framer skill and experience and ultimately results in a floor system that makes it easier for trades to install their products.

Reach your builder customers with this short, informative video that highlights the benefits of using floor trusses.

Many thanks to MiTek for generously funding the production of this video.

Framing the American Dream data suggests that installing floor trusses completes the task of framing a building’s floor system in almost half the time, requires less framer skill and experience and ultimately results in a product that is more reliable.

Reach your framer customers with this short, informative video that highlights the benefits of using floor trusses.

Many thanks to MiTek for generously funding the production of this video.

Learn how component manufacturers offer the most efficient structural framing solutions and how they've made a difference in communities across the country, allowing for the most effective use of time, labor and materials to frame all types of structures. Roof trusses, floor trusses and wall panels play an integral part in the structures you see every day.

Richard Brown and Jim Finkenhoefer met in 1986 at a Georgia Component Manufacturers Association meeting and later partnered in operating Truss Systems, a wood and cold-formed steel component manufacturing plant in Oxford, Georgia. In this podcast, these two entrepreneurs share how they successfully ran a truss plant together for almost 30 years on nothing more than a hand-shake agreement and remain friends today.

Austin Huskey, CEO of Huskey Truss and Building Supply in Franklin, Tennessee, shares what it was like growing up in a family-owned building material and component manufacturing operation. He explores what it’s like to be part of a national buying cooperative and how Huskey Truss is diversifying to stay ahead of the competition. He also discusses how their company is weathering the COVID-19 pandemic.

Components play an integral role in the structural integrity of a building, but in this case, they’re used purely for aesthetics. For the remodel of a Summit Credit Union’s “Inspiration Branch,” removable façades were built inside the lobby to represent financial and life goals dealing with travel, education and home ownership.

Components play an integral role in the structural integrity of a building, but in this case, they’re used purely for aesthetics. For the remodel of a Summit Credit Union’s “Inspiration Branch,” removable façades were built inside the lobby to represent financial and life goals dealing with travel, education and home ownership.

The BFS design team in Shelby, Alabama “collaborate on anything that doesn’t sit right,” says Thom Patton. One result: a roof that rests perfectly on a school building after a simplified build and easy install process.

QUALITY Speaks for Itself

QUALITY Speaks for Itself

Listed below are Frequently Asked Questions (FAQs) about SBCA In-Plant Wood Truss QC and SBCA’s Certification program. If you have any questions that were not addressed above, please contact SBCA staff.

Key changes are taking place within the truss and wall panel manufacturing community.

In March, SBCA undertook ASTM E119 floor assembly fire testing at NGC Testing Services in Buffalo, NY.

When designed and installed correctly, components can greatly reduce the time and materials required to frame a structure.

Designers and production crews found some creative ways to say goodbye to 2017 and hello to 2018.

A best practice for building designers: find a friend to check your load paths.

- SCORE’s focus on best practices and risk management helps protect the component business and saves CMs on precious training resources.

- In an effort to make the program and costs more understandable, SCORE certification requirements have been streamlined, while still focusing on industry best practices that matter most to CM customers.

- The new package pricing gives CMs the opportunity to meet SCORE requirements, at a reduced cost, and begin to reap the benefits from key SBCA programs and products.

Corrosion resistance is critical to ensuring connector plates hold up in adverse environments.

SBCA desires to promote the safe, economic, and structurally sound use of structural building components. Through this, SBCA is committed to providing the construction industry and fire service with accurate information regarding the use of metal plate connected wood trusses.

Truss manufacturing uses structural grades of 2x_ dimension lumber that is either visually graded or machine graded. The species of lumber used by a truss manufacturing operation is based on what is readily available in the regional market. In general, southeastern U.S. truss manufacturers often use Southern Pine; western manufacturers use Douglas Fir, Larch and Hemlock Fir; and northern manufacturers use Spruce-Pine-Fir.

Truss manufacturing uses structural grades of 2x_ dimension lumber that is either visually graded or machine graded. The species of lumber used by a truss manufacturing operation is based on what is readily available in the regional market. In general, southeastern U.S. truss manufacturers often use Southern Pine; western manufacturers use Douglas Fir, Larch and Hemlock Fir; and northern manufacturers use Spruce-Pine-Fir.