Search

- The wall panel business is completely different than trusses and has a learning curve.

- Before you start a panel operation, talk to panel manufacturers for specific tips.

- Make sure you compare the cost of labor for stick framed walls in your market to your own labor and overhead costs.

The 2015 Framing the American Dream study was unique in its use of floor panel systems. This infographic looks specifically at the labor savings of installing floor panels versus the floor installation in the stick-built home.

- Are you seeing the same objections to wall panels that you had with selling trusses?

- Labor demographics today will drive wall panel sales much like labor savings drove truss sales in the 1950s.

- The Extreme build helped Northeast Panel & Truss dispel misconceptions about wall panels and led their builder customer to embrace the product.

- The experience convinced Amedore Homes that wall panels are quality products that are also efficient and economical.

- The project couldn’t have been completed in the given timeframe without the use of wall panels, roof truss and floor trusses.

- Solar panels—devices that convert solar energy into electricity or heat—are often installed in trussed and conventionally framed roofs.

- To determine if a truss can withstand the load of a solar panel, add the value of the panel to the maximum top chord dead load capacity.

- If a panel can be applied to a conventionally framed roof with the same design load capacity as a truss system, the application should also work in the trussed roof.

The SBCA Wall Panel QC program helps manufacturers monitor the quality of wall panels they manufacture and provides the plant with a data management system. The program consists of inspecting wall panels and entering the data into the software program, allowing you to store data and create reports to assess plant quality. This program also offers an official SBCA Wall Panel QC 100% voluntary certification.

The SBCA Wall Panel QC program helps manufacturers monitor the quality of wall panels they manufacture and provides the plant with a data management system. The program consists of inspecting wall panels and entering the data into the software program, allowing you to store data and create reports to assess plant quality. This program also offers an official SBCA Wall Panel QC 100% voluntary certification.

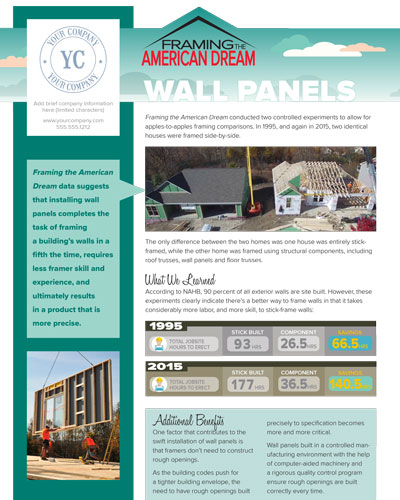

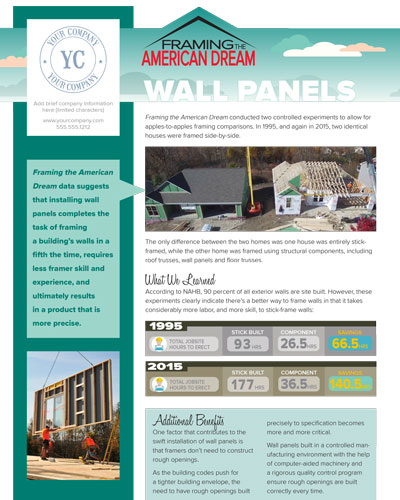

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less framer skill and experience, and ultimately results in a product that is more precise.

Reach your builder customers with this colorful, customizable brochure that highlights the benefits of using wall panels.

- A hybrid wall panel manufacturing system coordinates machinery options with expandable production software platform.

- The initial capital investment for wall panel manufacturing equipment is closely tied to your return on investment.

- The software package available through the hybrid approach offers expandability and works well with automated and manual equipment systems.

- This issue focuses on wall panel manufacturing. Turn to pages 20, 32 and 36 for wall panel-related articles.

- Two industry moguls leave the industry in 2008; check out their stories starting on page 44.

- Find out what’s going on inside SBCRI on page 42.

- When doing a material take-off for wall panels, identify the different wall types for each level.

- Wall panel manufacturers should have a pricing method that accounts for direct labor costs and plant overhead costs before adding a material markup and profit margin.

- The IRC requires vertical joints in braced wall panel sheathing to be connected to a common stud.

- SBCA has submitted a code change proposal that would allow a wall panels designed to the IRC to be built with the sheathing flush at the edges.

- The proposal will be heard at the May 2010 ICC Final Action Hearings.

- A bill was repealed in 1997 that allowed Caltrans to issue permits for transporting wall panels stacked horizontally.

- A coalition of CalESCA members, building contractors and homebuilders rallied to restore the bill that would allow wall panels to be hauled horizontally.

- In October 2007, AB 1612 was signed into law by Governor Schwarzenegger.

- As wall panels gain popularity, questions pertaining to sealed engineering requirements have increased.

- Can walls built in the shop rely on the prescriptive provisions of the building code?

- In the future, it is possible that component manufacturers will be responsible for providing sealed design drawings for their wall panel designs.

- A professional business plan is the first step to the long-term success of a wall panel plant.

- The business plan should be a fluid document that is modified often.

- The first phase of a new study conducted by U. S. Department of Agriculture Forest Service Forest Products Laboratory and North Carolina State University revealed that wall panel manufacturers employ a higher degree of manufacturing technology than do modular home manufacturers.

- Phase 2 of the study will include time studies of wall panel manufacturing facilities.

- Identify primary and secondary customers, most likely the general and framer.

- Some framers have the perception that panelizers are taking work from them, when in reality panels give them the ability to do more work because of decreased cycle times.

- Long-term marketing of wall panel products is best accomplished with comparisons of on-site versus off-site framing cycle times.

- A little education can go a long way in showing framers the overall time, labor and material savings of wall panels.

- In order to make wall panels cost effective, the builder’s framer has to buy-in to the concept.

- It’s true, wall panels may not be a fit in every market, but there are many markets throughout the U.S. that have yet to realize the full potential of these components.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in less time, requires less framer skill and experience and ultimately results in a more reliable building envelope. SBCA, with the help of its members, has developed a wide variety of resources and tools to help component manufacturers design, build and deliver high quality wall panels to their customers.

Dean Rana and Michael Miller have taken on the tough challenge of selling wall panel systems to Arizona framing contractors. In this episode, Rana and Miller give some insight into how they have convinced framers to move from sticks to panels and explain the value proposition they sell to the market. They also speak to how wall panels excel in a time when building material costs are rising.

In this episode, we rejoin Dean Rana and Michael Miller who provide more insight into how they have convinced framers to move from sticks to panels. They discuss the evolving needs of framers and builders and how they have altered their wall panel business to keep up. Dean and Michael also talk about characteristics of framers who succeed using wall panels versus those that don’t, and share how they're approaching young framing contractors.

One of the primary missions of SBCA is to help component manufacturers (CMs) gain greater market share. Traditionally, those efforts have been aimed at turning roof rafters into roof trusses, and that focus has paid significant dividends.

- Once you use wall panels, you realize how easy, safe and efficient they can be. You never want to go back.

- A framer-friendly mentality is essential for success.

- There are 12 educational sessions for attendees to choose from.

- Session themes include design, steel, wall panels, self-improvement, personnel and accident investigation.

- Early-bird registration deadline is August 25, so register now!

SBCA’s QC Committee and Board have undertaken a critical industry project entitled Digital QC and SBCRI’s 3rd Party Digital QA, which defines a quick and accurate method for component manufacturers to evaluate the quality of a truss anywhere and at any time.

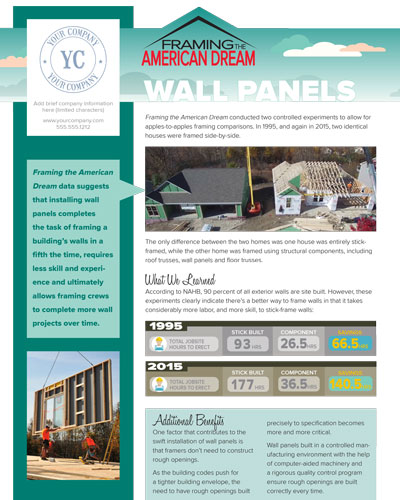

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less skill and experience and ultimately allows framing crews to complete more wall projects over time.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less skill and experience and ultimately allows framing crews to complete more wall projects over time.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less skill and experience and ultimately allows framing crews to complete more wall projects over time.

Reach your framer customers with this colorful, customizable brochure that highlights the benefits of using wall panels.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less framer skill and experience, and ultimately results in a product that is more precise.

Reach your builder customers with this short, informative video that highlights the benefits of using wall panels.

Many thanks to MiTek for generously funding the production of this video.

Framing the American Dream data suggests that installing wall panels completes the task of framing a building’s walls in a fifth the time, requires less skill and experience and ultimately allows framing crews to complete more wall projects over time.

Reach your framer customers with this short, informative video that highlights the benefits of using wall panels.

Many thanks to MiTek for generously funding the production of this video.

- Plywood and OSB design values are given; those that are doing repairs in your office should have a good feel for the similarities and differences.

- Plywood and OSB generally have similar design properties with a key exception of fastener strength where plywood will require more fasteners to be used.

- If a truss repair specifies only OSB, plywood should not be substituted without written permission from the registered design professional who prepared the truss repair design drawing.

- This issue of SBC Magazine focuses on wall panel manufacturing.

- Two component manufacturers are featured in this issue: Blenker Building Sys-tems and Clearspan Components.

- Additional feature articles spotlight whole house design concepts as they relate to the building components industry.